There are three major types of walk-in construction methods.

- Foamed-In-Place (Expanded Polyurethane)

- Hard Rail

- Laminated (Polystyrene)

These three methods use two primary insulation materials.

The R-factor of a material signifies how quickly heat conducts heat conducts across it. The higher this number the better the insulation works.- Urethane Foam

- Polystyrene

Our urethane foam has an R-factor of more than 32 (R32), most polystyrenes are only R19.

100% Edge to Edge Urethane Foam (R32)

100% Edge to Edge Urethane Foam (R32)

Unexpanded Urethane Perimeter (R20-R27)

Unexpanded Urethane Perimeter (R20-R27)

100% Polystyrene (R19)

100% Polystyrene (R19)

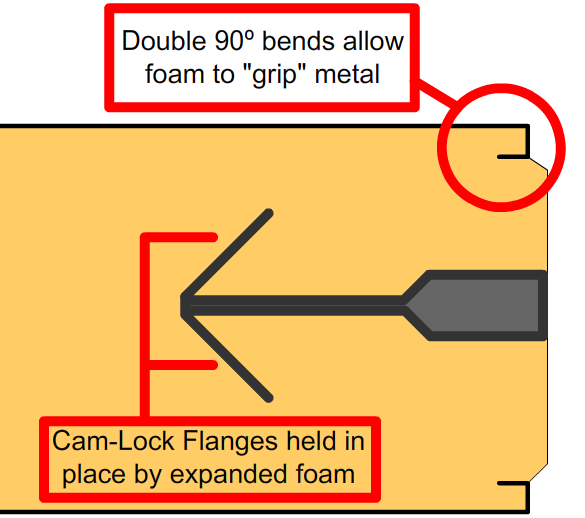

Engineering Advantages

Cross section of American Panel's Construction

Foamed-In-Place Manufacturing Means...

Higher R-Value (R32)Safer Manufacturing

Better Construction